How RF Anechoic Chambers Work

By Glen Dash, Ampyx LLC, GlenDash at alum.mit.edu

Copyright 1999, 2005 Ampyx LLC

A radio frequency “anechoic

chamber” is a shielded room whose walls have been covered with a material that

scatters or absorbs so much of the incident energy that it can simulate free

space. Its origins can be traced to

efforts to build aircraft which absorbed or scattered radar signals during the

Second World War. Recent innovations

such as the use of ferrite tiles, have greatly enhanced performance of these

chambers.

Anechoic chambers may seem to

operate through a bit of black magic, but the analysis of how they work is

really quite straightforward. Assume

for a moment that an electromagnetic plane wave (free space impedance = 377

ohms) strikes a wall at normal incidence. This can be modeled as a signal

passing down a transmission line with a 377 ohm characteristic impedance as

shown in Figure 1.

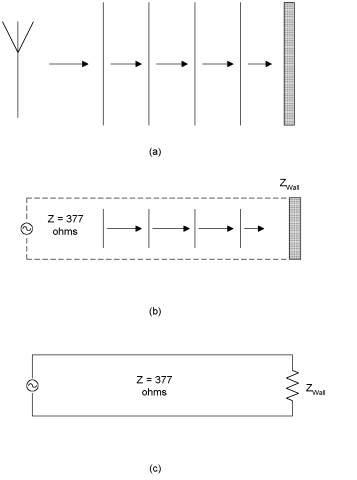

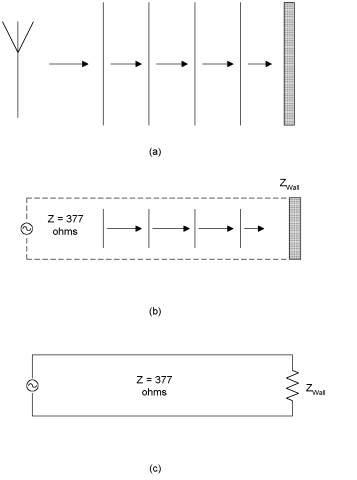

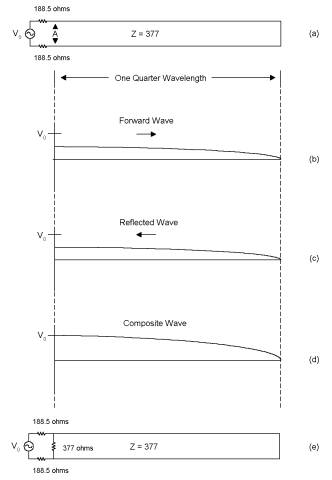

Figure 1: At (a), an antenna is

shown radiating a plane wave that impinges on a metal wall at normal incidence.

The antenna can be modeled as a voltage source and the resulting reflection

computed using a transmission line circuit model as shown in (b) and (c).

To create a reflection-less

chamber, we need, first of all, to understand how to send a signal down a

transmission line and not have it reflect back. Since the shell of the anechoic chamber is metal, our

transmission line model will have a shorted circuit at its termination. Since no energy is dissipated in our short

circuit load, all of the signals sent down the transmission line will be

reflected back. Our task is to find

something put in front of the wall that absorbs or scatters this energy.

One of the methods first

proposed to achieve this effect was through the use of the “Salisbury Sheet.”

The Salisbury Sheet is a sheet of paper that had been coated with a substance

to give it a surface resistivity of 377 ohms per square. It is placed exactly one-quarter wavelength

away from the metal wall. The Salisbury

Sheet makes the reflected signal virtually disappear.

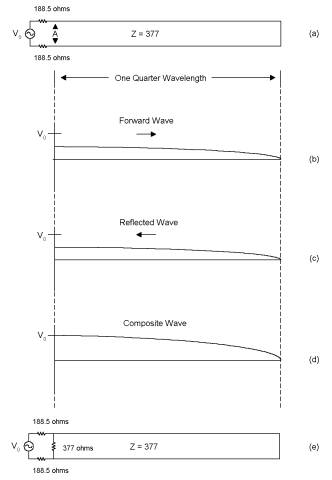

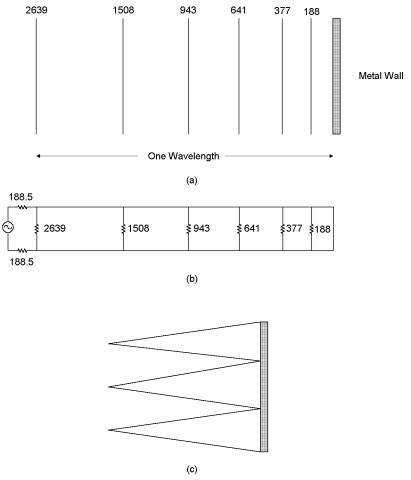

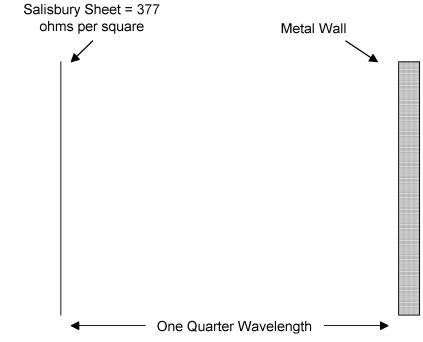

Figure 2: A shorted

quarter-wavelength long length of transmission line (a “shorted stub”) has the

impedance of an open circuit as seen from the source. By placing a resistor of 377 ohms near the source as in (e), the

impedance as seen from the source can be changed to 377 ohms.

To see how the Salisbury

Sheet works, look at Figure 2. Figure

2(a) shows a transmission line a quarter wavelength long with a characteristic impedance

is 377 ohms. The load is a short

circuit. Our voltage source also has a 377 ohm source impedance, divided into

two resistors of 188.5 ohms each (Figure 2).

When we turn the signal generator source on, a sine wave begins to

propagate down the transmission line towards the load (Figure 2(b)). Since the characteristic impedance of the

transmission line is also 377 ohms, the amplitude of this forward signal is

reduced by half (at least initially) and is equal to V0 /2. Reaching the load, a reflected signal is

sent back. Because the transmission line is a quarter wavelength long, the

reflected signal is exactly in phase with the transmitted one, and, as it

passes backwards towards the source, the amplitude of the voltage along the

transmission line doubles. At point A

in Figure 2(a), exactly one-quarter wavelength away from the load, the

transmission line has the impedance of an open circuit. For all practical purposes the transmission

line is indistinguishable from no load at all

-- it’s invisible.

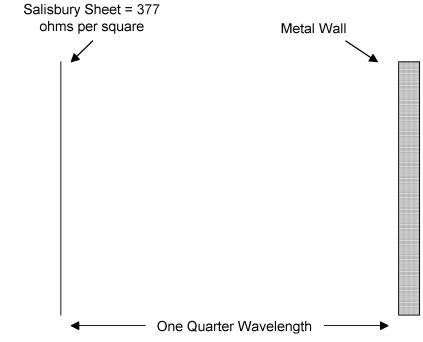

Figure 3: The Salisbury Sheet

provides anechoic effects at one frequency.

Placing a resistive sheet with an impedance of 377 ohms per square one

quarter wavelength away from the wall results in impedance as seen from the

source of 377 ohms.

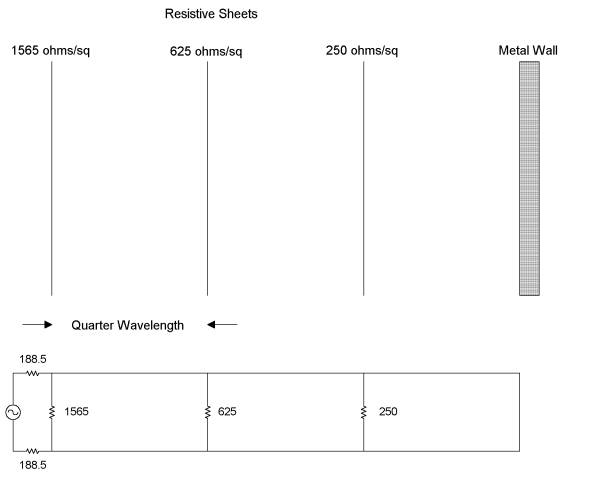

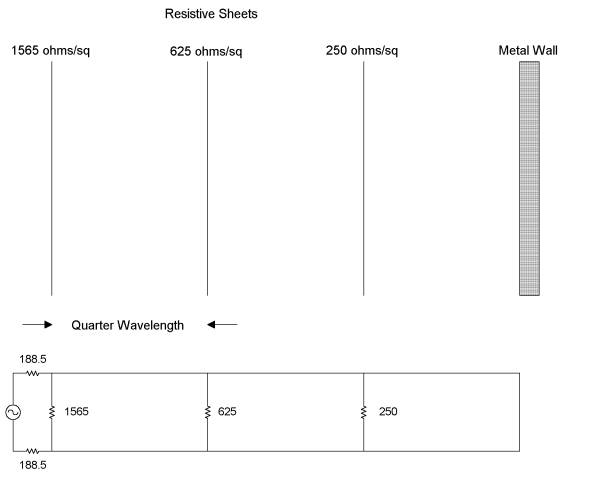

Figure 4:

The use of several sheets of resistive paper widens the bandwidth of absorbent

effects.

As

elegant a solution as a Salisbury Sheet is, its limitations are obvious. It only works at one frequency. In order to make the Salisbury Sheet work

over a larger range of frequencies, several sheets can be used as shown in

Figure 4. Here sheets of different

surface resistivities are placed at one-quarter wavelength intervals from the

metal wall. The transmission line

equivalent of such an arrangement is also shown. The arrangement reduces the reflection coefficient from 1 to less

than .1 (equal to a reduction of reflected signal strength of greater than 20

dB), and it works over a 2.5 to 1 bandwidth centered on l.

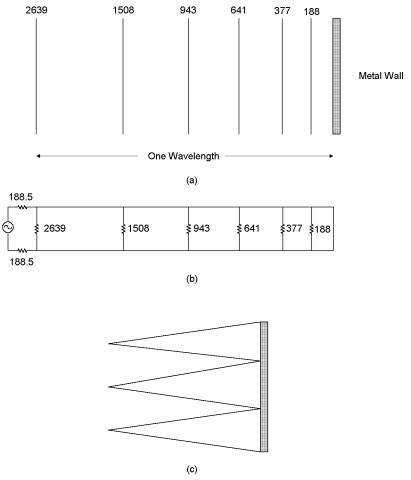

Another approach is known as

the “Jaumann Sandwich.” Here both the

resistances and the distances from the metal wall are tapered (Figure

5(a)). Reportedly, the Jaumann Sandwich

can achieve a 20 dB reduction in reflection over a 5 to 1 bandwidth (Reference

3).

Figure 5: The Jaumann Sandwich uses a staggered array

of resistive sheets and reportedly achieves a 20 dB reduction in reflected

signal over a 5:1 bandwidth. For the

case of normal incidence it can be modeled using the transmission line model in

(b). Pyramidal absorbers use much the

same effect to reduce reflection.

A modern implementation of

theses tapered techniques employs pyramidal absorbers (Figure 5(c)). The tapered shape of the pyramidal material

performs a role similar to the tapered resistances of the Jaumann

Sandwich. Many small reflections are

created as the electromagnetic wave passes into the pyramid and these

reflections tend to cancel out. To be

effective, however, the pyramids must be at least one half wavelength long at

the lowest frequency of interest. The

size of the pyramid needed to achieve this effect is mitigated somewhat by the

fact that the wavelength of the radio frequency signal as it passes through the

pyramidal material is shorter than the free space. It is reduced by a factor of:

Where:

lr =

Wavelength in media (that is, within the absorber)

er =

Permittivity relative to free space

Because of their size,

providing for anechoic effects below 100 MHz requires the use of technologies

other than pyramidal absorbers. In the

last 20 years, ferrite tiles have become widely used as an absorbing

mechanism. The key here is for the

ferrite tile to present an impedance approximately equal to 377 ohms. This is accomplished by making sure the

ratio of the permeability to the permittivity is equal to that of free

space:

That, in turn, is achieved by

keeping the ratio of mr to er equal to

377 ohms.

By itself that won’t prevent

reflections however. What makes ferrite

tiles work is that both the permeability and the permittivity are complex, so

that the material is lossy. A typical

ferrite material might have these properties:

This results in a

characteristic impedance of:

The complex permeability and

permittivity results in loss as the wave passes through the ferrite tile. This

loss is (Ref. 4):

The conductivity of the

ferrite tile can be considered to be zero. At 100 MHz, the loss for a

one-centimeter ferrite tile would be:

Therefore, as the wave passes

through the ferrite tile, it is attenuated by 11 dB. As is reflects off the metal surface behind the tile, the wave is

attenuated another 11 dB, for a total of 22 db of loss. Ferrite tiles will retain this absorbent

effect at all frequencies for which the permeability and the permittivity

retain these values.

References

1. Ramo, Whinnery & Van

Duzer, Field and Waves In Communications Electronic, John Wiley &

Sons, 1965.

2. Holloway, DeLyser, German,

McKenna & Kanda, “Comparison of Electromagnetic Absorber Used In Anechoic

and Semi-Anechoic Chambers For Emissions and Immunity Testing of Digital

Devices,” IEEE Transactions on Electromagnetic Compatibility, February, 1997.

3. Kraus, Electromagnetics,

Fourth Edition, McGraw-Hill, 1992.